Laser direct write (LDW) technologies

Group Leader - Dr Collin Sones

Group Members - Professor Rob Eason, Dr Ioannis Katis and Dr Peijun He

LDW techniques are one of the most versatile direct-write techniques, which uniquely enables the addition, removal and modification of a target materials without any physical contact. Additionally, these LDW techniques allow for the processing of complex materials with resolutions spanning more than three orders of magnitude, from millimetres to microns, and this makes these LDW process uniquely suited for fabrication of structures that are not possible via use of other techniques.

The LDW system normally consist of three key parts: a laser source, a beam delivery pathway, and substrate-material translation system. The heart of any LDW system is always the laser source. A wide range of lasers, from ultrafast pulsed lasers to continuous wave (c.w.) lasers, have been applied for LDW processing and the fundamental interaction of the laser with the target material is usually the main factor in the choice of the appropriate laser source and its corresponding parameters including the wavelength, pulse duration, divergence, beam quality etc., which directly determine the energy absorption efficiency and the subsequent material response.

To date, many kinds of LDW techniques have been used in science and engineering, and these techniques can be classified into three main categories: LDW subtractive procedures, where material is removed; LDW additive processes, where material is added; and finally LDW modification techniques. The technique our group has developed, and is described in detail below belongs to the last category, namely LDW modification wherein a laser is used to modify the target material or substrate in order to create user defined patterns within it. Our group has developed this technique with a focus on developing low-cost microfluidics-based sensors in paper that primarily have applications in point-of-care disease diagnostics.

Paper-based microfluidic sensors for point-of-care diagnostics

Point-of-care (POC) diagnostics, are specifically targeted at medical testing at or near the site of the patient’s care, without further need for a specialist laboratory environment and trained personnel. Such POC testing is facilitated through the use of uncomplicated, user-friendly and portable testing devices and much effort has been directed towards producing diagnostic test-kits that are not only smaller, faster and smarter, but also satisfy the elusive goal of being cost-effective – a vital requirement that ensures economic viability, since such POC test procedures may need to be performed repeatedly over potentially very large sample groups, that could even extend to an entire nation in the case of a pandemic.

Paper, in particular, with its varied characteristics, is now considered as a highly suitable alternative for fabrication of lab-on-chip (LOC) type POC devices, and many labs have focused their attention in this direction. In recent years, paper-based POC devices have been thoroughly researched and rapidly developed, especially for medical diagnostics and biochemical analysis. This is because of the urgent need for reliable diagnostic tools in developing countries where there is a lack of infrastructure, of trained personnel and also people within such countries cannot afford expensive technologies.

Compared with the polymer, silica or silicon-based microfluidic devices, paper-based devices offer considerable advantages. First of all, paper is readily available in a range of different forms and grades, which exhibit a range of different properties, such as porosity, wettability and its wickability. In addition, it is cheap and biocompatible, which makes it suitable for implementation of simple biological assays. Furthermore, paper is widely manufactured from renewable resources and can be easily stored and transported and it is also biodegradable and can be incinerated. Finally, an important feature that makes paper very attractive for microfluidic devices is its inherent ability to wick fluids via capillary forces, which avoid the need for external pumps which are necessary for the case of microfluidic devices on other above mentioned platforms.

As their name suggests, paper-based microfluidic devices normally consist of interconnected hydrophilic fluidic channels, which are demarcated by the hydrophobic walls, to guide and transport an analyte fluid, from a point of entry on the device to a reaction zone that has been pre-treated with specific reagents. Unlike glass, silicon or polymer substrates, where the fluidic channels are surface-relief structures that have been inscribed in these substrates, for paper-based devices the fluidic channels are formed inside and extend throughout the full thickness of the paper.

Introduction to our Laser direct write (LDW) paper patterning technology

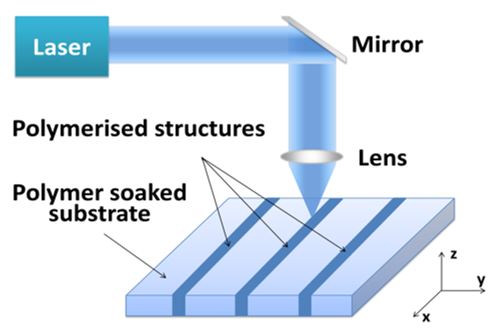

The basic LDW setup is shown in the schematic in Figure 1. During the LDW step, the laser beam is focused onto the substrate through a focusing lens. The substrate, normally a porous material, was mounted on a stage and translated either in two (x, y) or three directions (x, y, and z).

By programming the movement of the stage in the x-y plane, a user-defined two-dimensional (2D) structure can be patterned into the substrate. In addition, the axis z was used to adjust the position of the substrate (which was mainly at the focal plane of the lens).

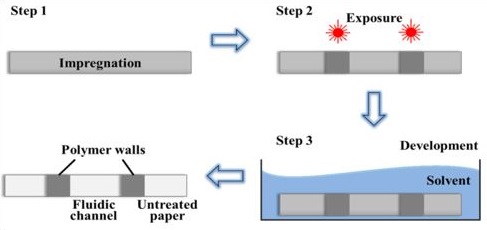

As described above, the paper-based devices are created by forming hydrophobic barriers that extend through the full thickness of the substrate, and demarcate the hydrophilic channels. The method we have developed to create fluidic patterns is based on light-induced photo-polymerisation, and is further described in the step-wise schematic in Figure 2.

In the first step, a porous substrate is fully soaked with a photopolymer, and then a laser beam is scanned across the substrate, as a second step, which leads to polymerisation of photopolymer in the laser-exposed areas. Finally, in the third step, a solvent is used during this development step to wash away un-polymerised photopolymer in the unexposed regions.

After evaporation of the solvent, the polymerised regions, which remain and extend throughout the thickness of the substrate, serve as hydrophobic barriers that define the channels that contain and guide fluids.

During the paper-patterning procedure, the light-induced photo-polymerisation is controlled by choosing the laser wavelength and adjusting the incident fluence (through laser output power or exposure time/scanning speed), so that any user-designed fluidic structure (including both the outline of the design and the integrity of the barriers) can be easily achieved in a single step.

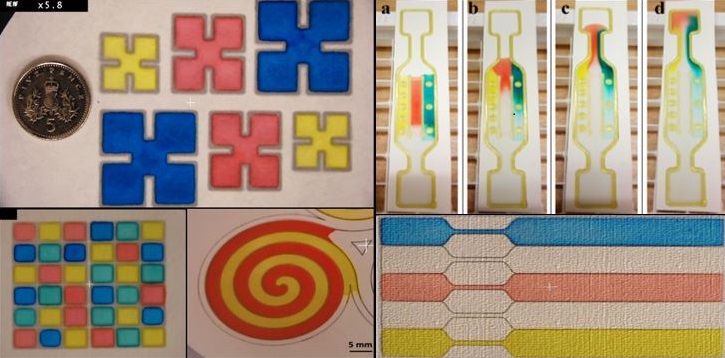

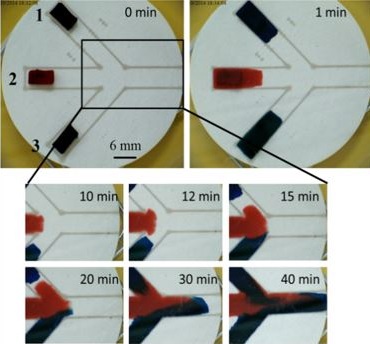

We have demonstrated that our simple, low-cost laser-based direct-write technique based on the principle of light-induced polymerisation can be used for the rapid fabrication of fluidic structures in porous materials such cellulose paper, nitrocellulose membranes and fabrics (Figure 3).

The laser-polymerised patterns form the hydrophobic barrier-walls of interconnected hydrophilic fluidic structures such as channels and wells. We have shown that using this method it is possible to create microfluidic channels and barrier-walls with dimensions of ~100 µm and ~ 60 µm, respectively, the smallest values that have been reported so far, which will allow for miniaturisation of the diagnostic sensor, and a corresponding minimal use of reagents.

With our existing laser-writing set-up, it is possible to pattern samples, using a c.w. laser, at speeds of a metre per second, and accounting for the time required for the pre- and post-processing steps needed to make a complete device, our estimate is that it is possible to fabricate at least one device per second.

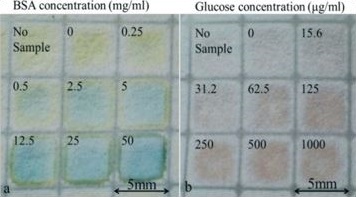

Overall, we believe that our LDW technique could be an ideal choice for rapid fabrication of paper-based microfluidic devices that can be used for a variety of applications such as clinical diagnostics and analytical chemistry, and the Figures 4-7 show examples of such devices.

Funded Projects and Awards:

- RAPID point-of-care infection detection and antibiotic-resistance TESTing enabled with laser-patterned microfluidic devices (RAPID-TEST); Funding body – EPSRC, £983,228, May 2017–April 2020.

- Laser-based engineering of paper for manufacturing fluidic sensors: (Lab-flo) (EP/N004388/1); Funding body – EPSRC, £750,942,Oct 2015–Oct 2018.

- Enabling testing of Antimicrobial Resistance to antibiotics via laser-patterned paper-platforms – Pump Priming Award from NAMRIP, £11,171, Mar2015-Feb2016.

- Laser-printable point-of-care sensors for low-cost medical diagnosis and disease monitoring (EP/K023454/1); Funding body – EPSRC, £232,528, May 2013-Dec 2014.

- Knowledge Mobilisation Fellows in Healthcare Technologies for Dr Collin Sones from the Institute for Life Sciences, University of Southampton; £44,550, Jan2103-June2104

- Innovation to Commercialisation (I2C/ICURe) Award from the SETsquared Partnerships; £50,000, Oct2104-Feb2105

Key academic and industrial collaborators:

- Professor Molly Stevens and Professor Jane Davies - Imperial College

- Professor Paul Elkington, Professor Andrew Walls, Dr Jude Holloway – Faculty of Medicine, University of Southampton

- Professor Dan Bader, Dr David Voegeli – Faculty of Health Sciences, University of Southampton

- Professor Bill Keevil – Biological Sciences, University of Southampton

- Several collaborators via Network on Antimicrobial Resistance and Infection Prevention (NAMRIP), University of Southampton

- Dr Bhaskar Somani – University Hospital Southampton , NHS Trust

- Mologic Limited, LGC Ltd, Alere Limited (UK), Ahlstrom International, Operon S.A., Coris BioConcept

Recent Publications:

- 7724 — C.L.Sones, Peijun He, I.Katis, R.W.Eason Laser engineering of three-dimensional (3D) structures in paper-based microfluidic devices

Conference on Lasers and Electro-Optics/Europe Munich 25-29 Jun 2017

Southampton ePrint: 407411

- 7720 — C.L.Sones, Peijun He, R.W.Eason, I.Katis Laser engineering of three-dimensional (3D) Structures in paper-based microfluidic devices

Lab-on-a-chip 2017 In press - 7630 — I.Katis, Peijun He, C.L.Sones, R.W.Eason Towards AMR testing using paper-based diagnostic sensors

SfAM Antimicrobial Resistance Meeting London 24 Nov 2016 (Invited)

Southampton ePrint: 403406 - 7597 — R.W.Eason, I.Katis, Peijun He, C.L.Sones Laser-printed fluidic channels for the manufacture of multiplexed paper-based diagnostic sensors

Advances in printed sensors London 8 Nov 2016 pp.2 (Invited)

Southampton ePrint: 401890 - 7510 — C.L.Sones, I.N.Katis, P.J.W.He, R.W.Eason Laser-direct-write (LDW) methods for fabrication of paper-based medical diagnostic sensors

BioDot workshop: Lateral Flow: Practicalities of Developing & Manufacturing Quantitative Assays Zaragoza 10-12 May 2016 (Invited)

Southampton ePrint: 400763 - 7509 — P.J.W.He, I.N.Katis, R.W.Eason, C.L.Sones Laser direct writing of programmable delays for fabrication of paper-based sensors that allow CRP detection

Biosensors 2016 Gothenburg 25-27 May 2016

Southampton ePrint: 400762 - 7508 — P.J.W.He, I.N.Katis, R.W.Eason, C.L.Sones Programmable delay in paper-based devices using laser direct writing

International Conference of Microfluidics, Nanofluidics and Lab-on-a-Chip Dalian 10-12 Jun 2016

Southampton ePrint: 400759 - 7507 — P.J.W.He, I.N.Katis, R.W.Eason, C.L.Sones Laser direct-write for fabrication of three-dimensional paper-based devices

Lab on a Chip 2016 Vol.16 pp.3296-3303

Southampton ePrint: 400761 - 7311 — P.J.W.He, I.N.Katis, R.W.Eason, C.L.Sones Laser-direct-write technique for rapid prototyping of multiplexed paper-based diagnostic sensors

Global Engage's Microfluidics Congress London 19-20 Oct 2015

Southampton ePrint: 388031 - 7156 — P.J.W.He, I.N.Katis, R.W.Eason, C.L.Sones Engineering fluidic delays in paper-based devices using laser direct-writing

Lab on a Chip 2015

Southampton ePrint: 381447 - 6870 — R.W.Eason, I.N.Katis, P.J.W.He, C.L.Sones Laser-polymerised fluidic channels for the manufacture of multiplexed paper-based diagnostic sensors

PR15 conference Villars, Switzerland 16-19 Jun 2015

Southampton ePrint: 384194 - 6779 — I.N.Katis, Peijun He, R.W.Eason, C.L.Sones Laser manufacturing for multi-analyte paper-based diagnostic sensors

European Conference on Lasers and Electro-Optics and the European Quantum Electronics Conference Munich 21-25 Jun 2015

Southampton ePrint: 379720 - 6773 — Peijun He, I.N.Katis, R.W.Eason, C.L.Sones Laser engineering of various porous materials for fabrication of paper-based microfluidic devices

European Conference on Lasers and Electro-Optics and the European Quantum Electronics Conference Munich 21-25 Jun 2015

Southampton ePrint: 379724 - 6561 — I.N.Katis, Peijun He, R.W.Eason, C.L.Sones Direct-write laser techniques for the manufacture of multiplexed paper-based diagnostic sensors

SPIE Photonics West - Microfluidics, BioMEMS, and Medical Microsystems XIII San Francisco 7-12 Feb 2015

Southampton ePrint: 379911 - 6552 — Peijun He, I.N.Katis, R.W.Eason, C.L.Sones Rapid prototyping of microfluidic channels in nitrocellulose using laser-direct-write patterning

SPIE Photonics West - Microfluidics, BioMEMS, and Medical Microsystems XIII San Francisco 7-12 Feb 2015 BO208-2 PW15B SPIE BiOS

Southampton ePrint: 379912 - 6551 — Peijun He, I.N.Katis, R.W.Eason, C.L.Sones Laser-based patterning for fluidic devices in nitrocellulose

Biomicrofluidics: Fabrication and laboratory methods 2015 Vol.9(2) pp.026503

Southampton ePrint: 384364 - 6617 — C.L.Sones, I.N.Katis, P.J.W.He, R.W.Eason Laser-direct-write methods for fabrication of paper-based medical diagnostic sensors

Photonics 2014: 12th International Conference on Fiber Optics and Photonics Kharagpur, India 13-16 Dec 2014 (Invited)

Southampton ePrint: 375892 - 6562 — C.L.Sones, I.N.Katis, P.J.W.He, B.Mills, M.F.Namiq, P.C.Shardlow, M.Ibsen, R.W.Eason Laser-induced photo-polymerisation for creation of paper-based fluidic devices

Lab on a Chip 2014 Vol.14(23) pp.4567-4574

Southampton ePrint: 384363 - 6522 — C.L.Sones, I.N.Katis, B.Mills, M.Feinäugle, M.F.Namiq, M.Ibsen, R.W.Eason Laser patterning for paper-based fluidics

SPIE Photonics West: Microfluidics, BioMEMS, and Medical Microsystems XII San Francisco 1-6 Feb 2014 8976-17

Southampton ePrint: 371881