Silica Fibre Fabrication

Optical fibre is at the heart of the Optoelectronics Research Centre’s history and research - In the Silica Fibre Fabrication group we are pushing the boundaries of what is possible in a strand of glass.

The Silica Fibre Fabrication group, led by Prof. Jayanta Sahu, focuses on the research of novel silica-based fibres and the methods used to fabricate them. We strive to create the most advanced fibres for each photonics application, while simultaneously developing the next-generation of fibre fabrication techniques.

As a critical technology that enables many research areas, our fibres are often developed in collaboration with other ORC research groups as well as in wider academic and industrial partnerships.

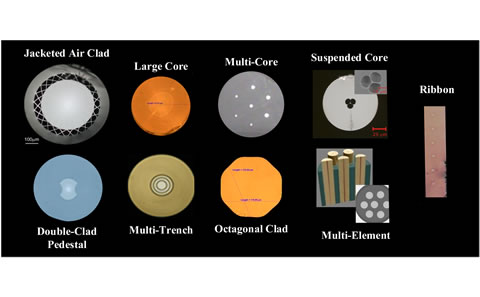

A few examples of the types of fibre we develop are:

- Large mode area and double clad fibres for high-power lasers

- Fibres for next-generation optical communications

- Birefringent fibres for sensing and telecoms

- Photosensitive fibres for Bragg gratings and distributed feedback lasers

- Novel dopant fibres for lasers, amplifiers, and sensing applications

- Highly non-linear fibres for sensing and non-linear photonics research

Our work encompasses all aspects of fibre fabrication, from the materials science and chemistry used to achieve a desired fibre composition, to the physics and engineering required to develop novel structures and fabrication techniques.

Background

The ORC has a rich history of silica fibre research - much of the foundational work on key fibre fabrication processes, such as Modified Chemical Vapor Deposition (MCVD), solution doping, and fibre drawing, was done here at the University of Southampton. Our expertise in fabrication is the cornerstone of fibre based research at the ORC, and has led to many world’s first demonstrations – including the Erbium doped fibre amplifier and, most recently, key results in high-power fibre lasers, and optical communications.

In addition to fundamental research on novel silica fibres, our work supports more than 100 other scientists within the ORC who are investigating applications of the unique fibres we create. Our success in crafting these innovative fibres has cultivated a multitude of external partnerships ranging from commercial supply of tailored specialty fibres to large-scale research contracts.

Having collaborated with more than a dozen industry partners and numerous university labs, we welcome the opportunity to work with new groups and new applications as we endeavour to push the limits of optical fibre capability.

Our Research

Current research projects focus on a variety of application areas, including:

Fibre for High-Power Lasers

• Large mode area (LMA) fibres

- Active dopants

- Double clad

- Low NA

- Photodarkening-free

- Active dopants – Ytterbium, Neodymium, Erbium, Erbium and Ytterbium, Thulium, Holmium

- Novel structures to improve thermal performance and efficiency

New laser wavelengths & laser performance enhancement

- Active dopants – Thulium, Erbium, Neodymium, Ytterbium, Holmium, Praseodymium, Samarium, Gadolinium

- Bismuth doped fibre

- Novel geometry fibre

- Fibre materials research and spectroscopy of doped fibres

Novel fibres for sensing, non-linear optics, Bragg gratings, and telecoms

- Ultra-high power density and tailored non-linearity

- Fibre-optic gyroscope optimised fibres

- Poled silica fibres

- Photosensitive fibres

- Ultra-high and low linear birefringence

- Circular birefringence and spun fibre

- Multi-element and multi-core fibres

Our Capabilities

To support our research we employ the latest, state-of-the-art fibre fabrication facilities along with a comprehensive suite of design and characterization techniques. Among these are:

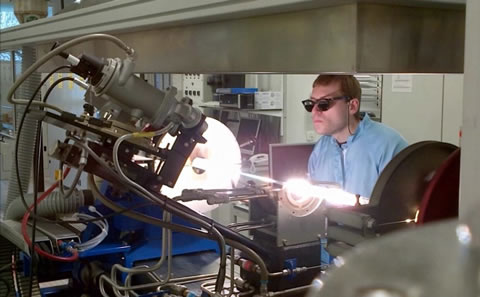

• 2 custom MCVD lathes

• Outside Vapor Deposition (OVD) system

• Support for a wide variety of dopants with both gas phase deposition and advanced solution doping techniques for active fibre fabrication

• Comprehensive glass-working facilities including ultra-sonic drilling/milling

• State-of-the-art draw tower

• Fibre proof testing

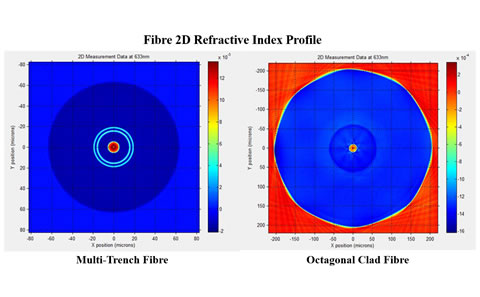

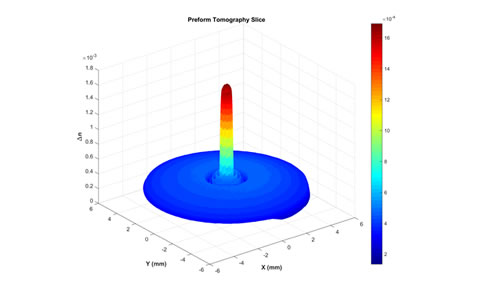

• Full preform and fiber analysis capability including tomography, index profiling, stress measurement, dopant characterization, OTDR covering a wide wavelength range up to 2µm, and rare earth spectroscopy

• Optical measurement facilities for complete fibre performance evaluation as well as laser and/or device level characterization in both active and passive fibres

Work With Us

We always welcome new opportunities for collaboration. If you are interested in working with us, or you would like to find out more about our group, please contact Prof. Jayanta Sahu.

Silica Fibre Fabrication group members

No members in database.